-

Highlight

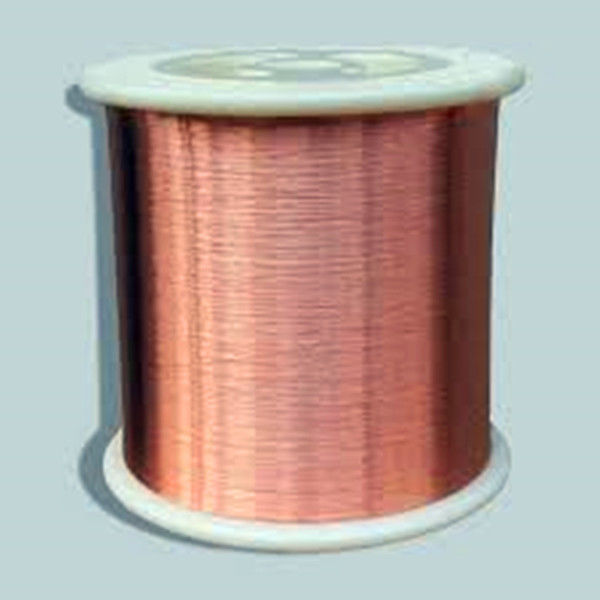

EMI Shielding Wire Mesh

,EMI Shielding Copper Wool

,EMC Chamber Copper Wool

-

TypeRC Filter

-

Transfer FunctionLow Pass

-

Package TypeSurface Mount

-

Nominal Center Frequency50

-

3dB Bandwidth10M

-

Insertion Loss100dB

-

Input Impedance50

-

Stopband Attenuation3dB

-

ApplicationMri Rf Room

-

ColorCopper

-

Wire Diameter0.07mm

-

Moq2.5Kg

-

Lead Time7-10 Workdays

-

PortShanghai

-

Place of OriginJiangsu, China

-

Brand NameHAOZHUO

-

CertificationCE RoHS

-

Model NumberH

-

Minimum Order Quantity>=1 Rolls

-

Price$300.00

-

Packaging Detailscarton

-

Supply Ability100 Roll/Rolls per Week

EMI Shielding Wire Mesh Copper Wool 99.9 For EMC Chamber

EMI Shielding Copper Wool 99.9% Copper For EMC Chamber

What are the types of shielding for EMI/RF?

The primary types of EMI shielding are shielding directly on a printed circuit board, or around the seams of an enclosure. Depending on the application, a board level shield, finger stock gasket or fabric over foam gasket would be preferable.

What are common applications of the different shielding types? Which shielding types are preferred for different applications?

Selecting the right type of EMI shielding solution begins with analyzing many factors such as the environment, RF frequencies of concern to the project and mechanical requirements.

When picking a board level shield, what are the benefits of Nickel Silver versus Tin-Plated Steel?

Tin-plated steel and nickel silver perform at a relatively similar rate, however the difference between the two is the frequency ranges that each performs better at. Tin plated steel is preferable if trying to block low frequency waves from creating interference, while nickel silver blocks mid to high frequency waves more effectively. Each will block EMI/RF across different ranges but specialize within their specific ranges.

| Product description | |

| Name | copper foil |

| Material | 99.8% copper |

| Width | standard 1350mm |

| Thickness | standard 0.105mm(3oz),0.14mm(4oz) |

| Feature | EMI shielding |

| Application | faraday cage,MRI room |

Product description:

1. The product structure is based on copper foil as the substrate, conductive acrylic adhesive as the adhesive, plus release paper.

2. Three-tier architecture is very suitable for cutter mold or the metal mold die-cutting, Can be flat cutter or round cutter to die-cutting.

3. The width of the product available from 3mm ~ 380mm. Standard length is 50m., also do 100m, 150m or longer, save customers the trouble of frequently reloading.

| Part Number | Backing Material | Thickness of Backing (mm) | Total Thickness (mm) | Holding Power Min/inch | Adhesion Strength kg/25mm | Adhesive Component | Shield Efficacy 10MHz~ 1GHz (dB) | Conductivity z-ohms | Integrated thermal conductivity (W/mK) |

| XPH0M123 | Copper Foil | 0.012 | 0.030±0.01 | ≥1440 | >0.8 | Acrylic | ≥60 | <0.03 | 60 |

| XPH0M183 | Copper Foil | 0.018 | 0.050±0.005 | ≥1440 | >1.0 | Acrylic | ≥60 | <0.03 | 60 |

| XPH0M253 | Copper Foil | 0.025 | 0.06±0.005 | ≥1440 | >1.0 | Acrylic | ≥60 | <0.03 | 80 |

| XPH0M353 | Copper Foil | 0.035 | 0.070±0.005 | ≥1440 | >1.0 | Acrylic | ≥60 | <0.03 | 90 |

| XPH0M503 | Copper Foil | 0.050 | 0.085±0.005 | ≥1440 | >1.0 | Acrylic | ≥60 | <0.03 | 110 |

| XPH0M753 | Copper Foil | 0.075 | 0.11±0.01 | ≥1440 | >1.0 | Acrylic | ≥60 | <0.03 | 130 |

| XPH0MA03 | Copper Foil | 0.100 | 0.135±0.01 | ≥1440 | >1.0 | Acrylic | ≥60 | <0.03 | 160 |

| XPH0MA23 | Copper Foil | 0.125 | 0.15±0.015 | ≥1440 | >1.0 | Acrylic | ≥60 | <0.03 | 170 |

| XPH0MA53 | Copper Foil | 0.150 | 0.20±0.02 | ≥1440 | >1.0 | Acrylic | ≥60 | <0.03 |

190

|

| Product Features |

| shielding ED copper foil |

| thickness 0.009--3mm, width 10-1380mm |

| easier to make a faraday cage, EMI room |

| generally 400-500kg/roll |

| Physical Properties |

| Density:8.9g/cm³ |

| Electrical conductivity(20°C):min 90%IACS for annealed to temper 80%IACS for rolled to temper min |

| Thermal conductivity(20°C):390W/(m°C) |

| Elastic modulus:118000N/m |

| Softening temperature:≥380°C |

| Certification |

| meet the technical conditions GB/T 5187-2008 standards. |

|

in accordance with ISO9001-2000 Quality system requirements

|

![]()

![]()